Exciting Image Transfer Option

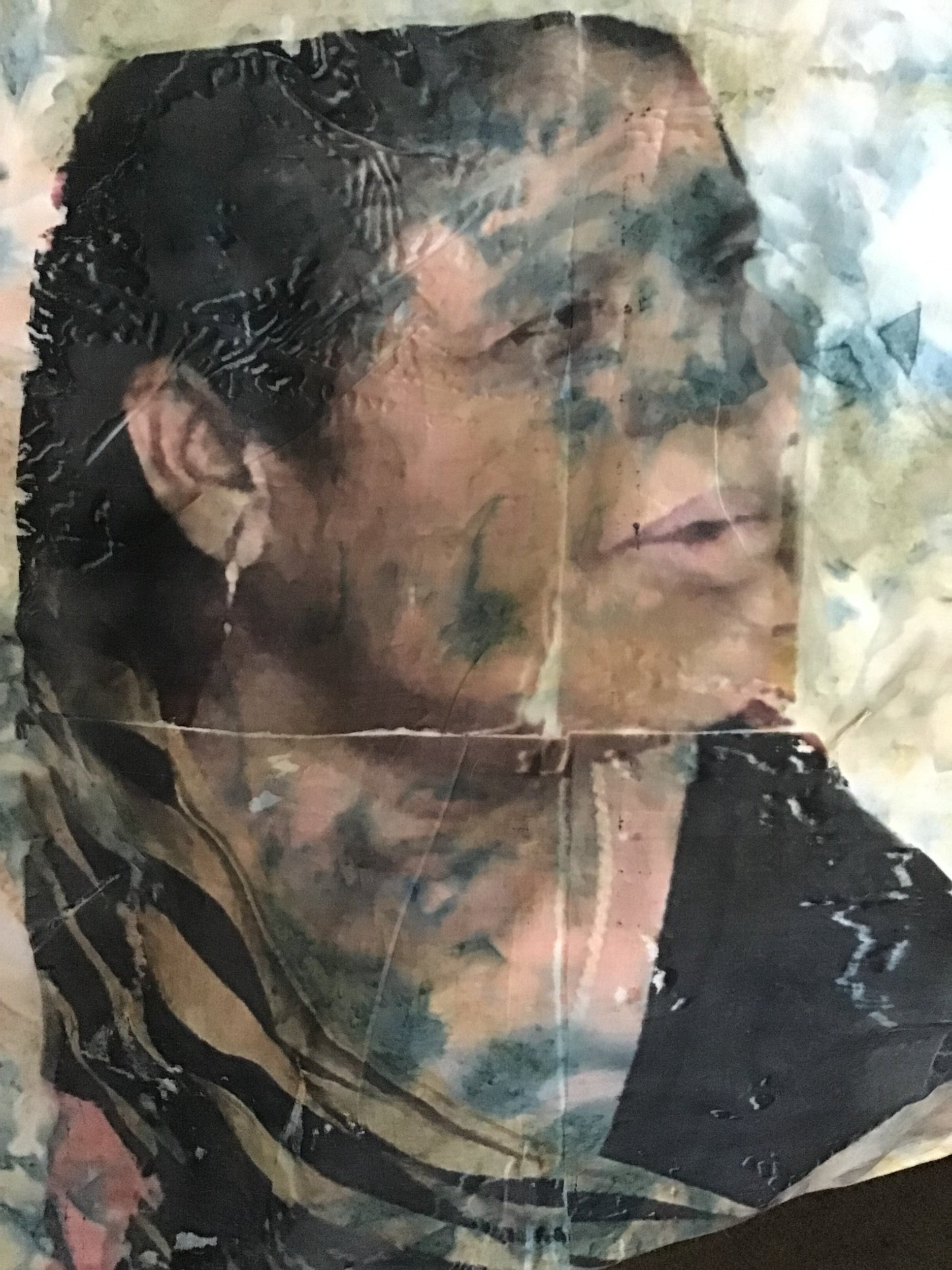

I am getting ready to start work on a series of Faces Of India from my trip to India last year. I have been working on Wen Redmond’s course using different media and from that learned about a free ap called imagy.ap that allows you to split an image into parts - each of which can be then be printed. In he example above I printed four images (you can see where the joins are) first onto HP overhead transparency. I use an inkjet and you must use OHP for inkjets as the standard laser ones will not adhere the ink. Or if you have inkaid you could create a useable transparency by putting a layer of inkaid (maybe even Golden’s ground would work but I haven’t tried that yet). Let the ink dry on the transparency.

I joined the four sections of my transparency with clear packing tape so that I could see the whole image and audition fabric for the background. I had read about using citrasolv as a image transfer agent but this product is not available in new Zealand. So I had a play with some general citrus clearner from the supermarket.

I sprayed the area of the fabric where I wanted the image to transfer to with the citrus cleaner then carefully placed the joined transparencies onto that are. Spray the fabric NOT the transparency or the ink will blob on the transparency film. Then I rubbed the image. I used a barren but anything that gives some pressure will work. I carefully lifted the edges of the transparency and sprayed a bit more cleaner onto the areas where the transfer didn’t seem to be working quite as well.

The output photo above is the result. I am delighted. This image has been transferred onto some cotton eco dyed fabric that was a bit wet in process so the images were blurry but it suits this application well. I intend to stitch over the photo so I was not too concerned about the “join” lines in the image. I do think the fabric needs to be scoured to remove any finish if using a commercial fabric as the next piece I did was not as clear a transfer and I think that was to do with the commercial finish on the fabric.

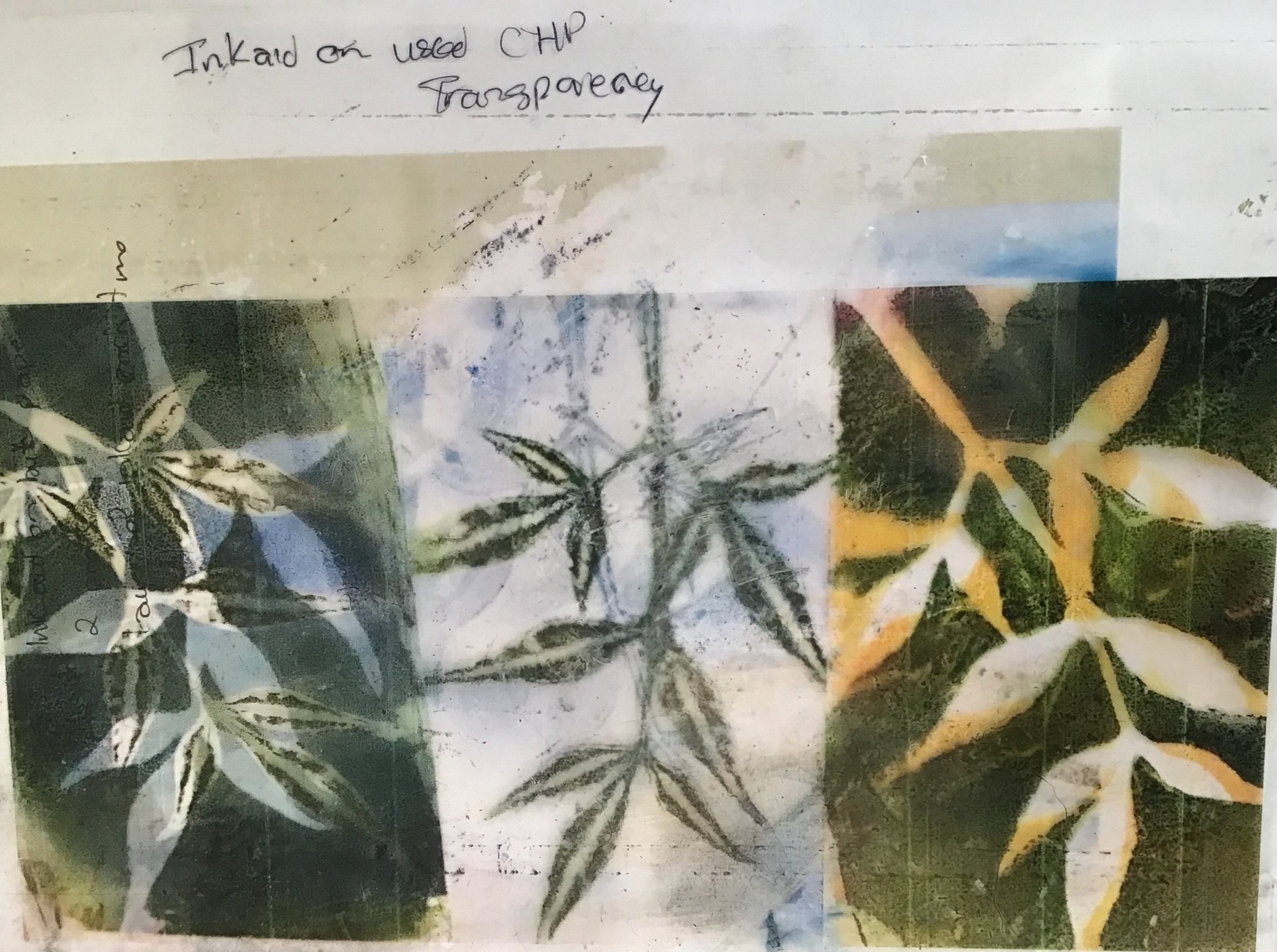

The inkjet OHP’s that work best are the ones that have the rough side for the ink to adhere. This “roughness will transfer with the image and the OHP will be pretty clear after use. Trying to recycle as much as possible, I painted the cleared OHP with Inkaid and found that I could reuse that transparency. Below is the printout on the transparency from that trial. In this example you can see a little of the man’s blue shirt at the top of the transparency. This area could be cut off before applying the citrus cleaner transfer. As this was just an experiment to see if i could reuse the OHP I didn’t bother to clean up the transparency first. You could use citrus cleaner and a baby wipe or similar to clean the residue off the OHP before treating with inkaid.

I really like the ability to use the transparency to audition fabrics and choose the placement of the transferred image

The image below is on unscoured commercial fabric and the image did not transfer as cleanly as the one above. It could be that the lighter skin tones played a part. for my purposes it won’t matter too much as I intend to thread paint over the image but it is something to consider if using an image that is to stand alone